Torch applied membrane application is a method used in the installation of modified bitumen roofing systems, which are popular for flat and low-sloped roofs. In this process, modified bitumen sheets, which consist of asphalt reinforced with polymers such as styrene-butadiene-styrene (SBS) or atactic polypropylene (APP), are adhered to the roof substrate using a torch to melt the underside of the membrane and bond it to the substrate.

Here’s an overview of the torch applied membrane application process:

- Surface Preparation: Before installing the membrane, the roof surface must be cleaned, free of debris, and dry. Any repairs to the substrate, such as patching cracks or holes, should be completed before proceeding.

- Base Layer Installation (Optional): In some cases, a base layer of modified bitumen membrane may be installed as a foundation for the torch-applied membrane. This base layer provides additional waterproofing and reinforcement.

- Membrane Placement: Rolls of modified bitumen membrane are rolled out onto the roof surface, starting from one end and working towards the other. The membrane sheets are typically overlapped to create a watertight seal, with the side laps (longitudinal seams) overlapping by a certain distance and the end laps (transverse seams) overlapping by several inches.

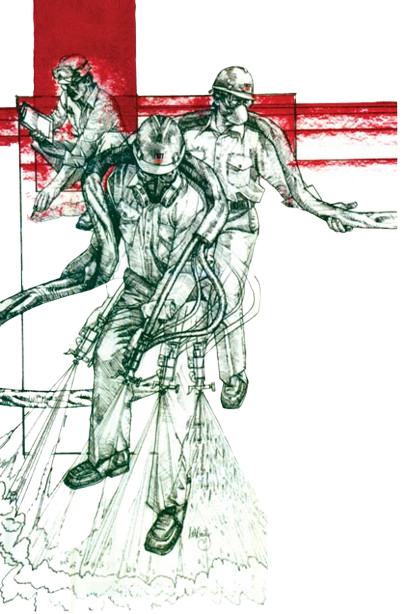

- Torch Application: A roofing professional, typically using a handheld propane torch, applies heat to the underside of the membrane sheets as they are rolled out. The torch melts the asphalt underside of the membrane, activating the adhesive properties and bonding it to the substrate. Care must be taken to avoid overheating or damaging the membrane during this process.

- Seam Sealing: As the membrane sheets are installed, the seams between them are sealed using a combination of heat and pressure from a roller. This ensures a tight and secure bond between the overlapping membrane layers, preventing water infiltration through the seams.

Final Inspection: Once the membrane installation is complete, a final inspection is conducted to ensure that all seams are properly sealed, securely installed, and the membrane is uniformly adhered to the substrate.

Torch applied membrane application offers several advantages, including:

- Rapid installation.

- Excellent waterproofing performance.

- Resistance to UV radiation and weathering.

- Flexibility to accommodate building movement.

- Long-lasting durability.